Tension

Tension is a startup focused on innovating in furniture assembly systems, funded by Iovine & Young Academy.

Role

Design & Manufacturing

Design & Manufacturing

Tasks

Market & User Research

Research & Development

Product Development

Production Manufacturing

Financial Projection

Branding Pitching

Market & User Research

Research & Development

Product Development

Production Manufacturing

Financial Projection

Branding Pitching

Team

Colin Wong

Aaron Wong

Colin Wong

Aaron Wong

Skills

Project Management

Product Market Fit

Customer Discovery

User Journey Map

Value Engineering

Presentation

Project Management

Product Market Fit

Customer Discovery

User Journey Map

Value Engineering

Presentation

Product

The Tension shelf takes concepts from the field of architecture and structural engineering and implements it in a smaller scale. The shelf is designed to be collapsible and expandable to a 4’x4’x11” shelf that doesn't compromise on functionality, aesthetics or user experience. Installation takes approx. 2 mins and collapsible to 1/8th its original size. Our assembly does not uses screws so that there's no stripping of materials from screws or nails as with other furntiure assemblies.

Research

I put off buying a shelf in 2017 for 3 years because I was afraid of the physical toll of needing to move this giant shelf in and out of apartments in the future. Then during the first year of COVID, I helped my frugal friends move 6 times, thats 6 times of moving without hiring movers, when I still don’t have a shelf. However, this was when the disposable culture of furniture was most evident to me.

In the us in 2018 it was estimated that 12.1 million tons of furniture waste was produced which amounts to 4.1 percent of total waste generated.Over 80 percent of this waste goes to landfills and most of this furniture were made in the last 10 to 15 years. This is because of the disposable culture that the current industry has set. They are built with cheaply made composite materials, which cannot be recycled, not built to last and have a very short lifespan.

Insights

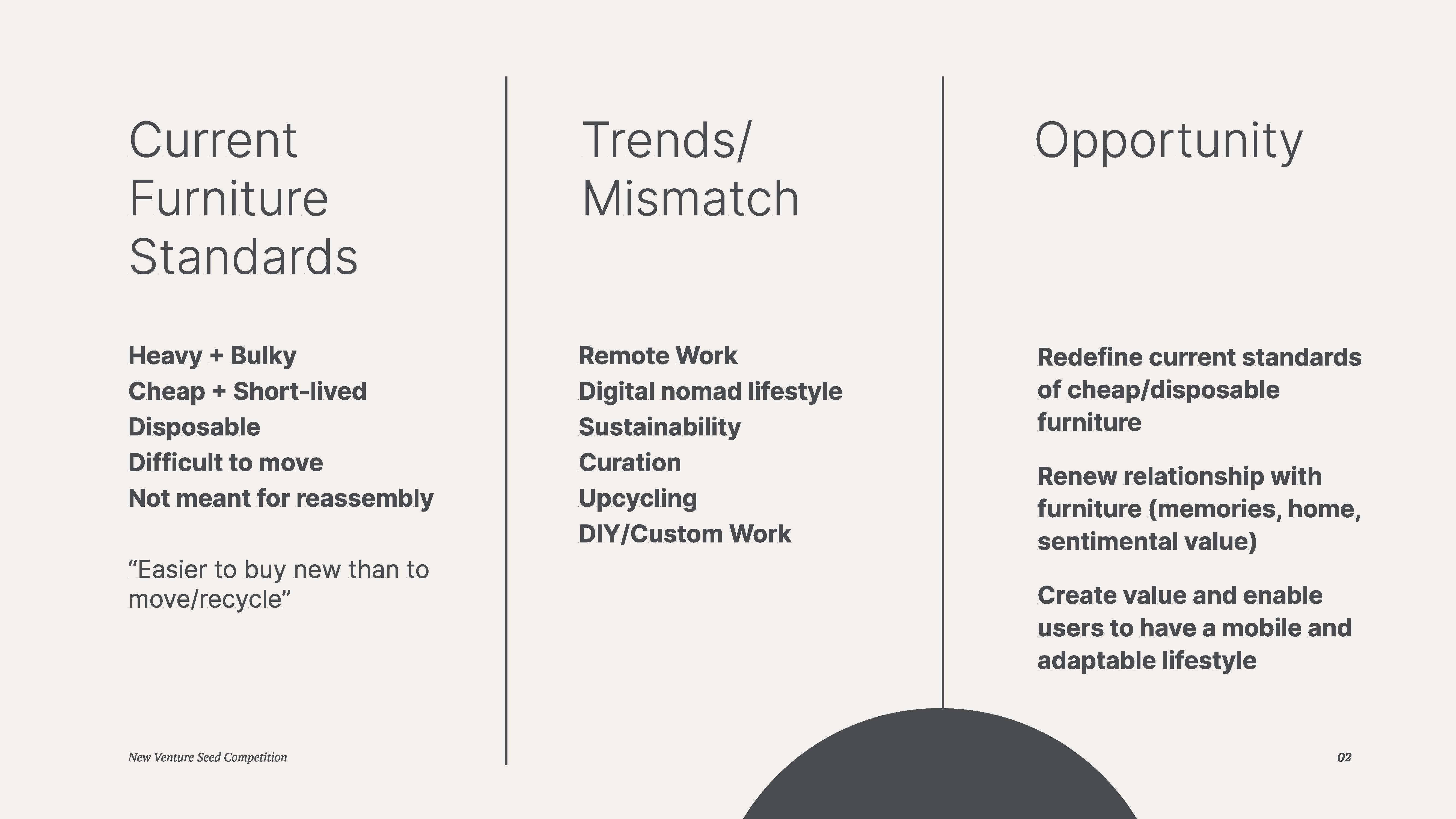

In conducting user interview and surveys amongst college students and young professionals, we found that there is a mismatch between the current furniture standards, their needs, and where our opportunity lies.

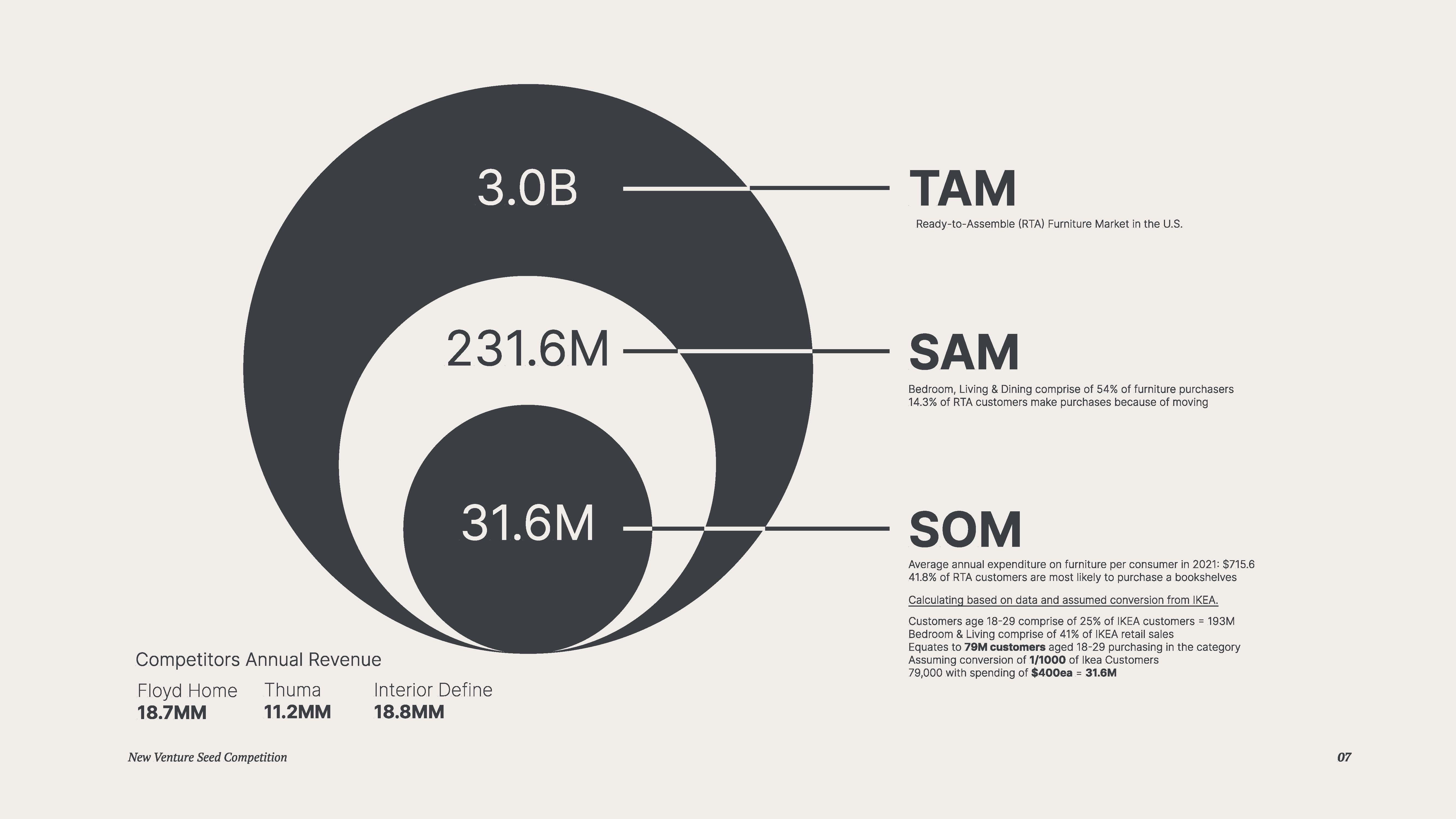

The Market & Competitors

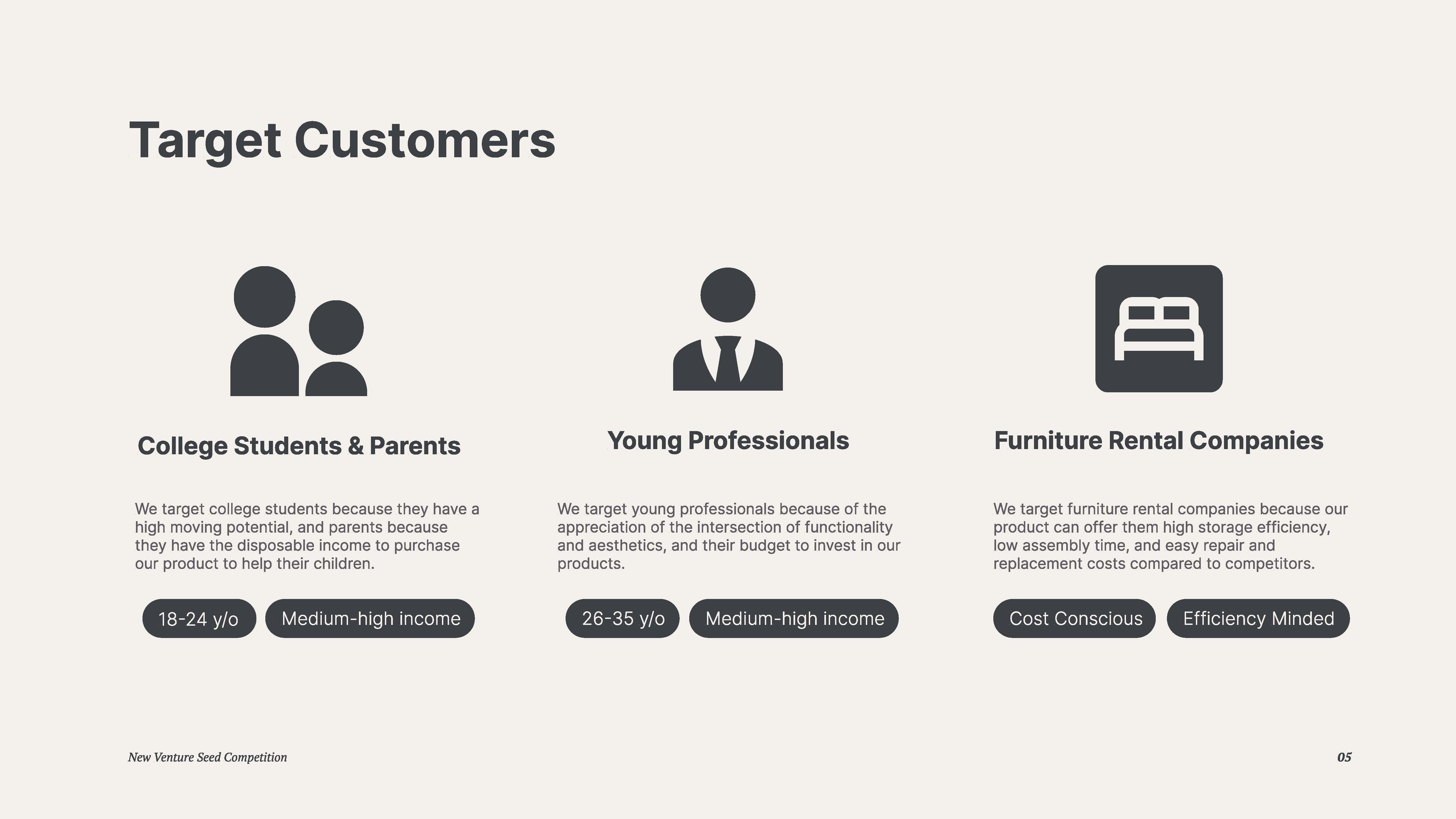

Product currently on the market that serves our target segment are split into two camps. 1. Budget friendly, and 2. Made to move with you. Reassembly mechanisms come with a cost, leaving a gap between $80 shelves and $800 shelves where we can carve a space in the market for Tension products.

Design Criterias

These are the design criterias we set for each of the product and prototype we make, a guideline with criterias that each product has to adhere to, so that we don’t just design cool things, but stay focused on the goal.

Product Development

Inspiration: West Coast Transmission Building (Qube), Vancouver.

Process

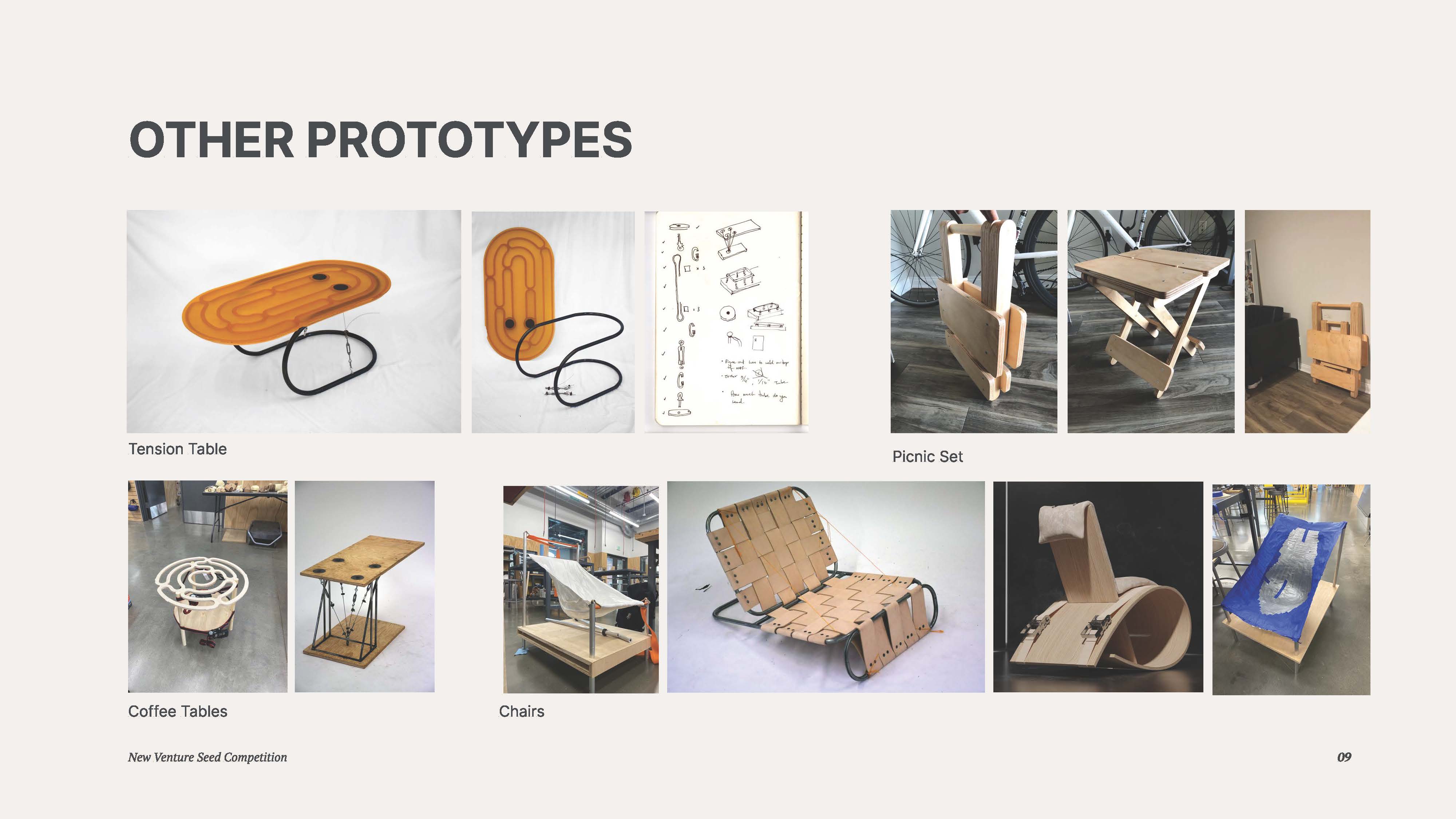

We have three prototypes, each moving closer to a production quality product, and achieving the price we need. The first was a proof of concept, the concept of the Westside Transmission Building in Vancouver, Canada, where floorplates were hung off of a concrete core with steel cables, rather than supported from the ground up. The second prototype pushed further into collapsability, but had cost issues due to the custom metal work required. The third and most recent prototype was focused on value engineering, we refined the form factor, parts we were using, and were able to achieve a cost reduction of 60% from the previous prototype.

Operations & Roadmap

Our team is really what allows us to develop these products successfully. We combine backgrounds in architecture, industrial design, mechanical engineering and business to ensure that the products are structurally sound, aesthetically pleasing, and financially feasible to the cost targets we have.

Our team!

Yes, we are siblings.